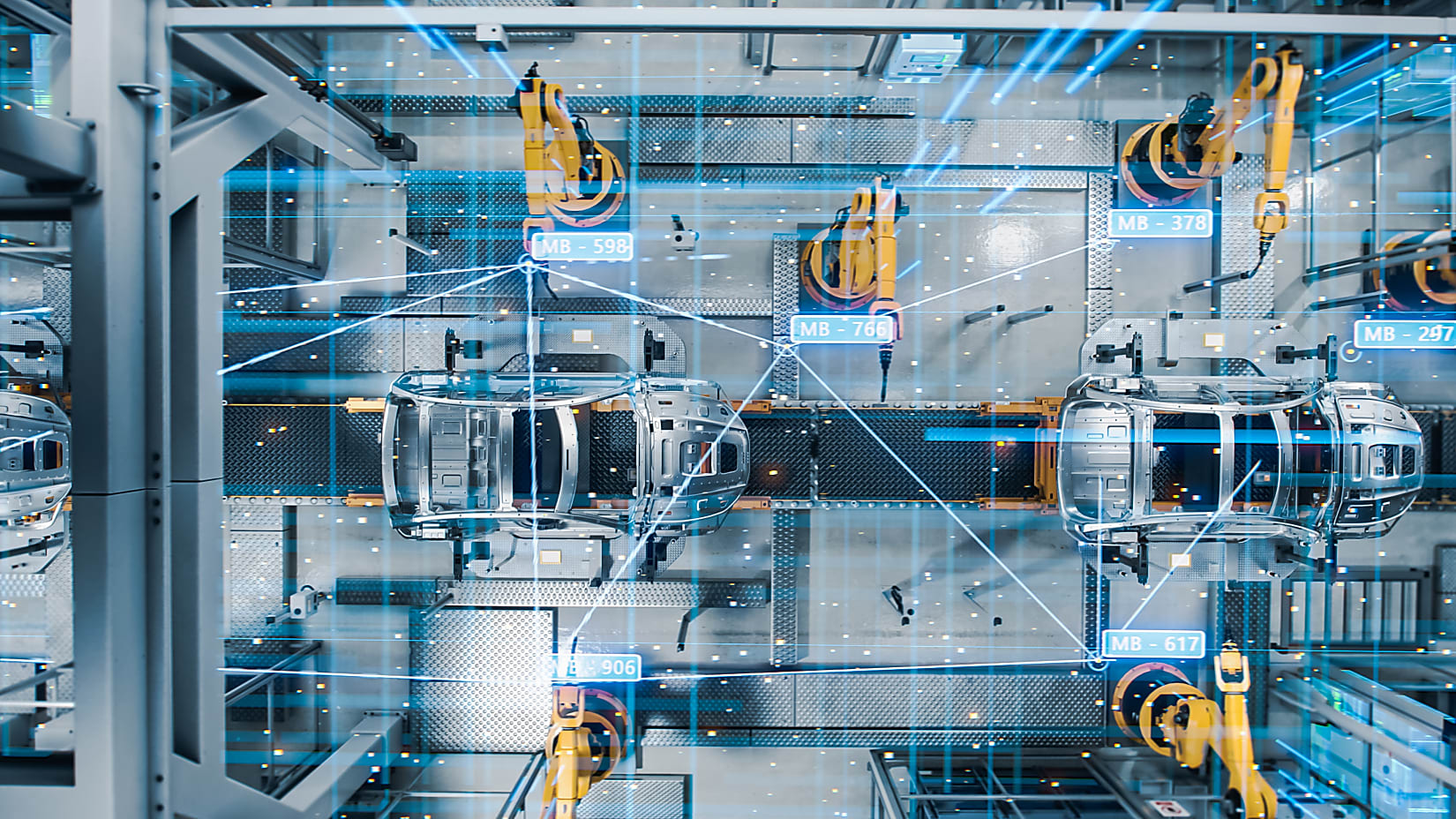

Wireless communication on factory floors

Wireless communication in harsh industrial environments and demanding applications is nothing new. Wireless has been around for more than 40 years using proprietary radios.

It has become more and more accepted on factory floors and in the last few years as standards like Wi-Fi (IEEE 802.11), Bluetooth (IEEE 802.15.1), and Zigbee have become dominant.