Q&A

How can I access water treatment equipment remotely?

With Ewon Remote solutions from HMS Networks, it is possible to remotely access PLC-based machines to do troubleshooting and maintenance from anywhere. The remote solutions are secure and penetration-tested and enables quick access to machines with a laptop or tablet, just like being on site.

What are the benefits of the Ewon remote access to a machine?

With Ewon you will save time and money thanks to the Talk2M Service for remote access to any field control system to program, diagnose, update, calibrate, or monitor them.

Can I also monitor remotely the machine

Sure! With Ewon Flexy you will have availability of real-time data of field assets using native industrial protocols (including serial, ethernet, and Profibus). Data can even be collected directly from sensors since the Ewon optionally includes digital and analog I/Os. No data loss and timestamp at origin even if there is a network outage thanks to the local buffer in the Ewon. The Ewon Visualization Tool available to all Talk2M Pro users will allow the monitoring of real time and historical data, as well as alarming, maintenance and reporting

Is remote access secure?

Strong OT Cybersecurity is a central element for the digitalization of any water or wastewater treatment system

Ewon solutions by HMS are certified according IEC 62443 and ISO 27001 standards. This remote access solution implements the latest security technology to secure production from external threats.

How can I integrate machine data with my SCADA

The standard protocol supported by most SCADA systems is OPCUA. Our Ewon Flexy can read from any device, manage the data at the edge, and deliver it to the SCADA thanks to the embedded OPCUA server, making it extremely easy and fast to integrate PLCs or legacy devices (serial ports or directly from sensors) to the SCADA

How do I connect equipment in water treatment plants?

Communication is key for a well-functioning water treatment plant. PLC systems need to communicate with other PLC systems, machines need to be accessed remotely, new machines need to be integrated. And the entire plant network needs to be monitored and failsafe. With Anybus gateways information exchange between machines is easy and fast

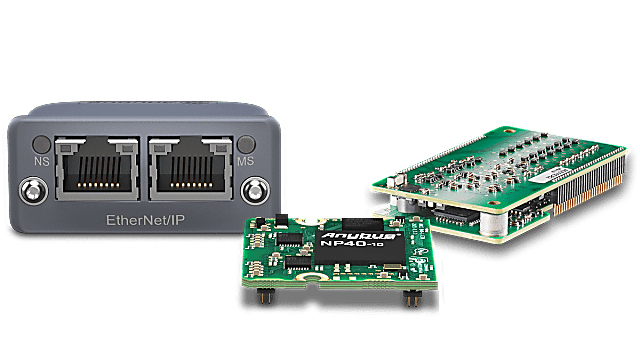

I am a pump manufacturer, how can I integrate it in a Profinet network?

With our Anybus embedded product line you can easily integrate industrial communications to your pump controller or to other devices. Check our Product page for more information

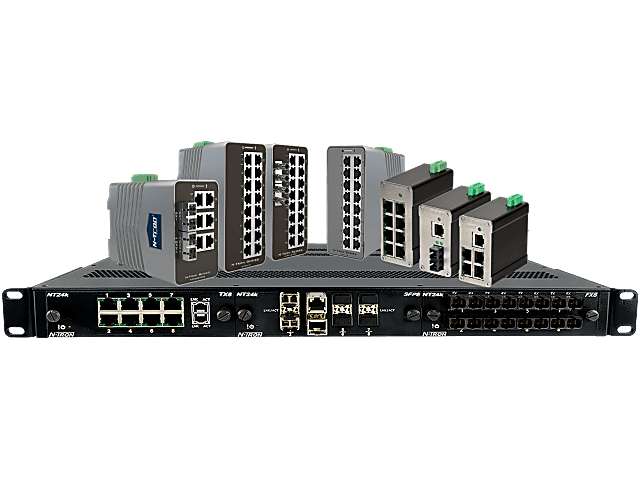

I am having some trouble with the plant Industrial Network, how can HMS help me?

Having online monitoring tools to predict possible network failures and, in any case, being able to react very quickly is essential for the smooth operation of the plant. For this purpose, the Anybus Diagnostics product line ensures a reliable network infrastructure for industrial networks such as PROFIBUS, PROFINET, EtherNet/IP, and other industrial Ethernet standards. The portfolio includes products that help field technicians monitor, analyze and troubleshoot efficiently, both onsite and remotely, thus avoiding undesired downtime.

Do you provide training on your products

Yes! Visit our Training page for online training at your own path.