Are you ready for 2027? Learn how the EU Machinery Regulation will reshape compliance and safety requirements by 2027

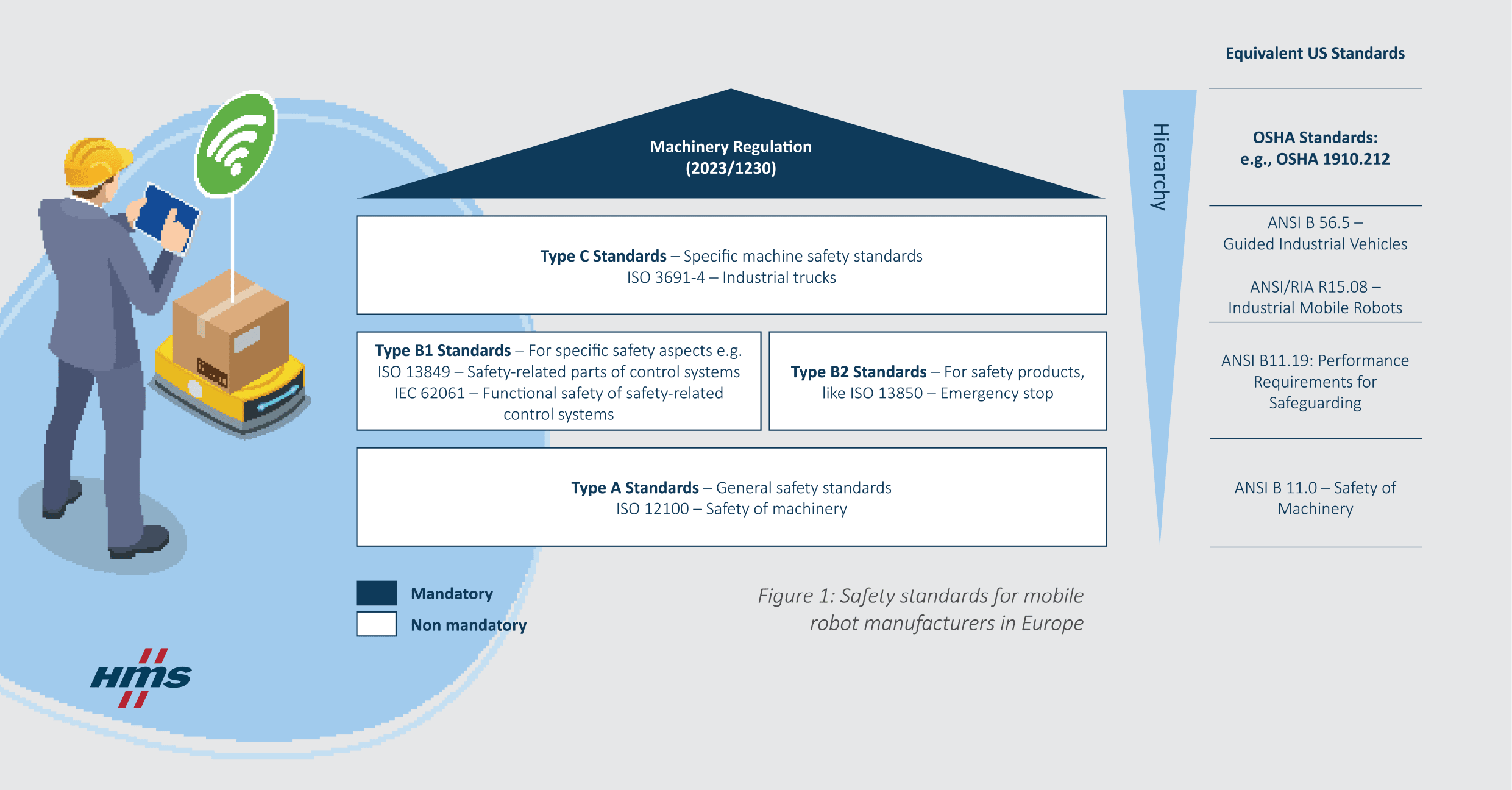

Industrial automation is entering a new era, with safety standards expanding to meet the demands of smarter, more connected machines. From January 2027, compliance with the new EU Machinery Regulation (2023/1230) will be mandatory. Without it, CE marking and access to the EU market will no longer be possible.

The current EU Machinery Directive (2006/42/EC) has long served as the foundation for CE marking and safety compliance in Europe. But with the rise of autonomous systems, mobile robots, and software-driven safety features, it’s no longer sufficient.

The new EU Machinery Regulation introduces:

Further updates to the Machinery Regulation are expected before it comes into force, so manufacturers should stay informed and be ready to adapt.

One of the most critical challenges in modern safety design is ensuring reliable wireless communication for mobile machinery. Safety-related signals, such as emergency stops or positioning data, must be transmitted reliably and without delay, even in complex environments with hundreds of devices.

Protocols like PROFIsafe and CIP Safety are well-suited for wireless transmission. While all three protocols, including FSoE, follow the black channel principle, FSoE’s summation frame approach is not ideal for Wi-Fi environments. In contrast, PROFIsafe and CIP Safety benefit from using standard, routable Ethernet frames over PROFINET and EtherNet/IP, making them more robust for wireless applications.

A well-designed wireless network is essential because safety protocols rely on network timeouts that are often set above 200 ms. The longer the timeout, the longer a system may remain in a non-safe state. In practice, this means that higher timeouts require greater physical safety distances between people and machines.

Want to explore how safety protocols perform over wireless?

Read our Safety protocols go wireless whitepaper:

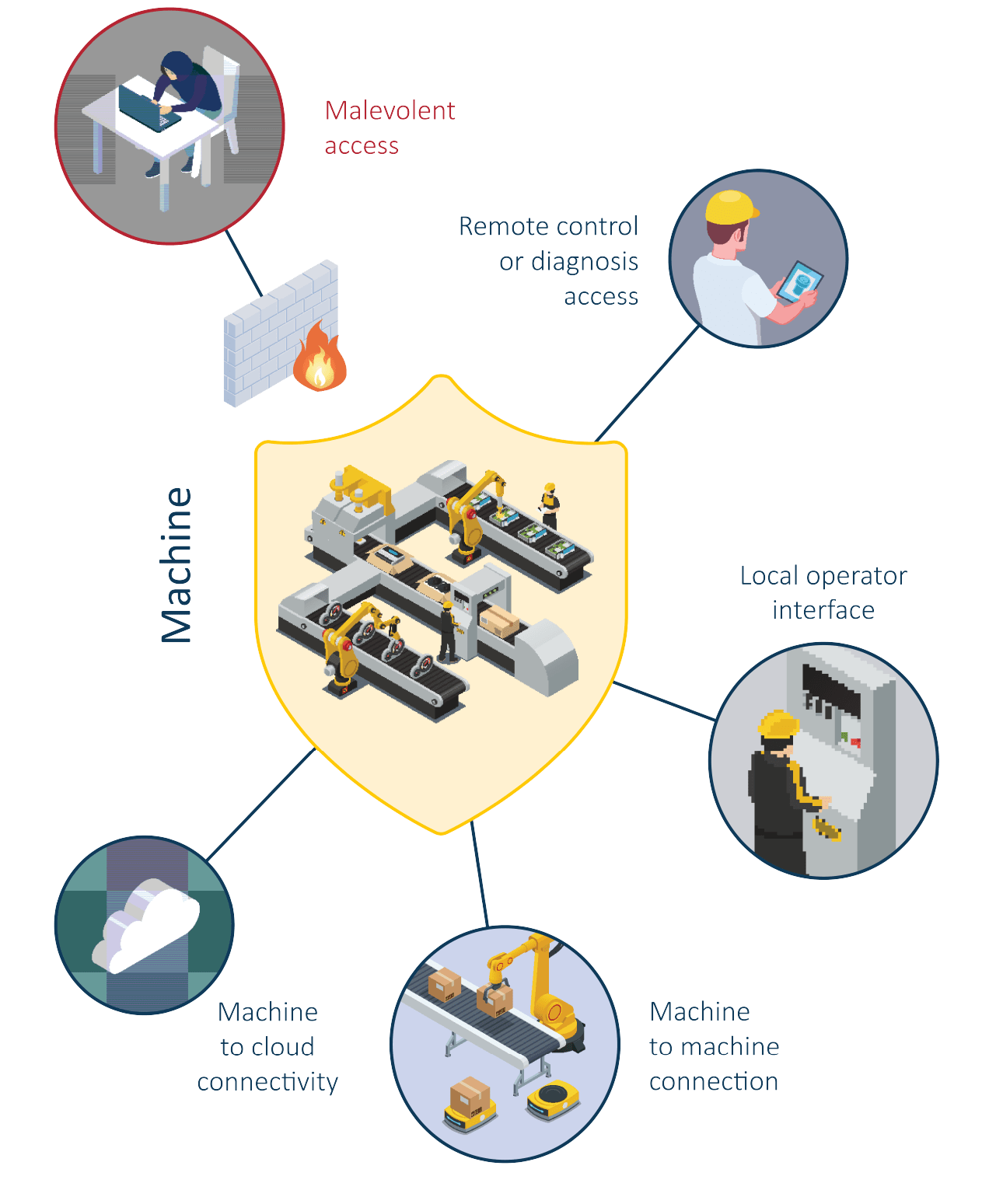

The new regulation also addresses IT security, a growing concern as machines become more connected. In the future, manufacturers must ensure:

Safety and security are no longer separate domains. Together, they form the foundation for resilient, trustworthy, safe automation systems.

To stay ahead of the 2027 deadline, manufacturers should:

The new regulation will bring clarity, but also complexity. Early action is the key to avoiding delays and ensuring market readiness.

For a deeper dive into the new EU Machinery Regulation: Read our whitepaper Are You Still Safe in 2027?

Learn more about HMS’ functional safety solutions here: