By 2040, Europe is projected to face a shortage of more than 2 million workers per year, with a significant portion of this gap hitting automation engineering roles. Experienced engineers are retiring, and younger generations are slower to enter the field. At the same time, production complexity continues to grow, especially with the integration of IIoT, AI-driven systems, and flexible manufacturing technologies.

For machine builders and automation solution providers, the question isn’t just "How can we automate more?", it’s "How can we make automation systems easier to design, deploy, and operate for a broader, less specialized workforce?"

The answer lies in usability and human-centered design (HCD), two principles long championed in the software and consumer technology sectors, but still underutilized in industrial automation.

Historically, automation platforms have been designed by engineers for engineers. Interfaces are often dense, unintuitive, and require deep domain knowledge to configure or troubleshoot. For many automation engineers, even simple tasks like setting up a fieldbus network or configuring a PLC require digging through manuals, deciphering cryptic error codes, and trial-and-error testing.

As labor becomes scarce, this model is no longer sustainable.

Usability - the degree to which a system can be used easily and efficiently by its intended users, can dramatically lower the skill barrier for operating and maintaining factory automation equipment. Streamlined setup processes, guided workflows, visual diagnostics, and standardized user experiences are no longer “nice-to-haves”, they are essential.

In fact, many of the most forward-looking machine builders in Europe are now embedding usability into their core product strategies, not just to satisfy end users but to make their own engineering teams more productive and reduce total cost of ownership for customers.

Human-Centered Design (HCD) goes deeper than interface design. It’s about rethinking the entire product lifecycle, from engineering and commissioning to daily operation and maintenance, around the real-world needs, constraints, and mental models of users.

For automation solution providers, this means:

The result is not just fewer support calls or reduced training time. It’s a measurable improvement in deployment speed, system uptime, and user satisfaction, key metrics that directly impact customer loyalty and long-term profitability.

So how does this address the automation labor shortage?

By making systems more usable and human-centric, you:

This is not theoretical. Companies that have invested in usability improvements report deployment time reductions of up to 40%, and significant cuts in service intervention rates.

For Product Managers and Engineering Managers, usability and HCD are no longer secondary considerations. They are business levers that can:

Moreover, with the upcoming EU regulations around digital product responsibility (such as the Cyber Resilience Act), there is now a regulatory push toward clearer, safer, and more predictable system behaviors, further reinforcing the case for human-centered design.

For machine builders and automation solution providers who want to embrace usability and HCD, here are three practical starting points:

In a world where automation talent is becoming scarcer and production environments more demanding, usability and human-centered design are no longer optional, they’re strategic necessities.

Machine builders that embrace this shift will not only build better products but also build stronger customer relationships, unlock new business models, and help close the labor and skills gap that threatens to slow down Europe’s manufacturing transformation.

Now is the time to design automation systems not just for machines, but for the humans who use them.

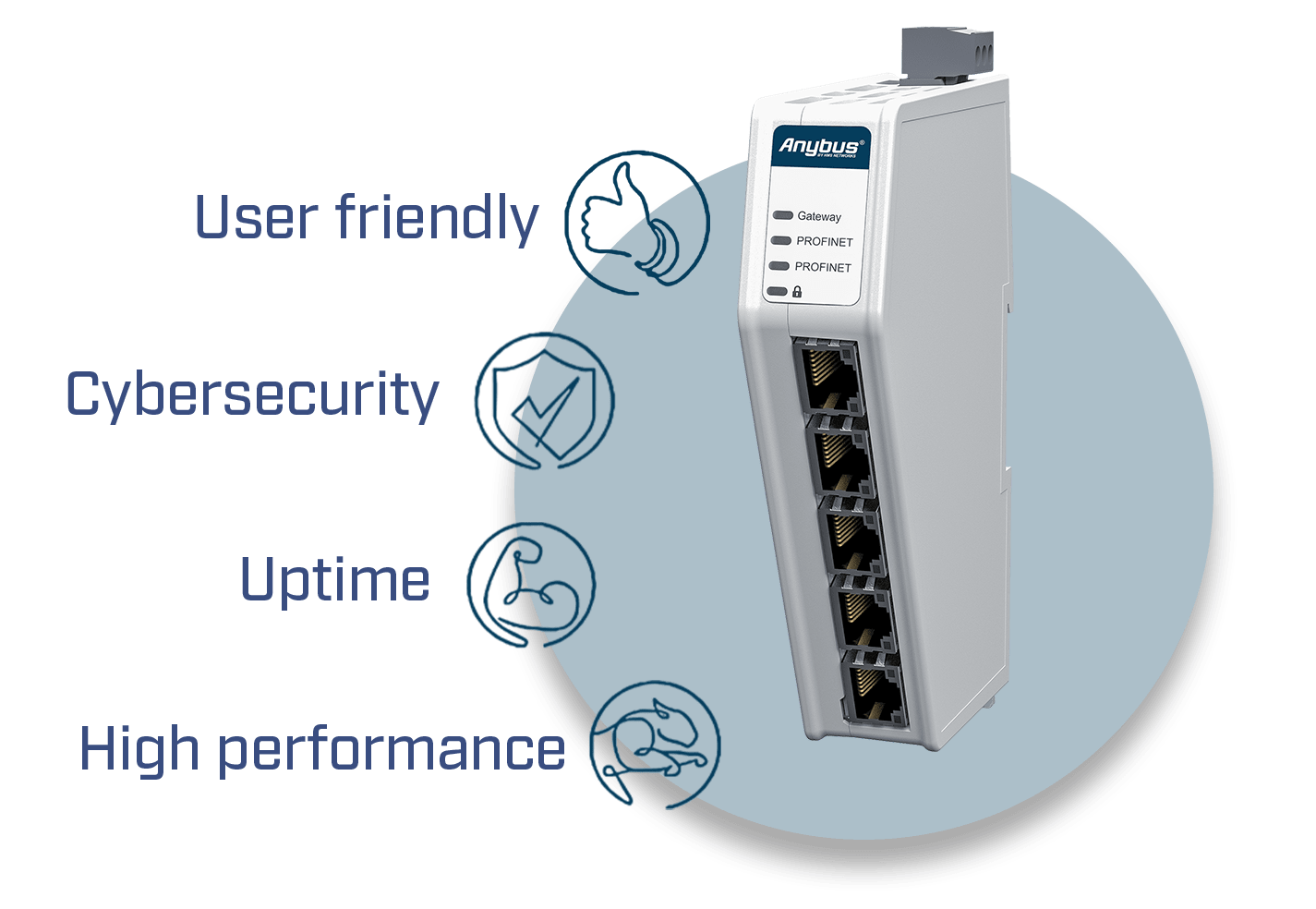

If you’re interested in seeing a real-world example of these principles applied in factory automation, take a look at the Anybus Communicator. It’s designed specifically with usability and human-centered design in mind, making industrial network connectivity faster, simpler, and more accessible for automation engineers at every skill level.

For more information on Anybus Communicators and how they simplify industrial connectivity, click the button below:

Thierry Bieber is the Business Development Manager at HMS Networks Market Unit in Central Europe. Thierry has over 25 years of technical and market experience in industrial communication and machine infrastructure applications, and actively participates in standardization organizations such as PI (PROFIBUS & PROFINET International).