Last week, our engineers were called to a paper mill to troubleshoot a “minor” PROFIBUS configuration change. As we’ve all heard before: “We only changed this parameter, then changed it back, so nothing else should be affected.” Famous last words!

Analyzing the network

It’s a familiar story for our engineers. The PROFIBUS parameters had been changed and then reverted, but a couple of Decentralized Periphery (DP) devices stubbornly refused to start up.

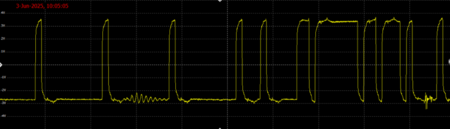

The first step in troubleshooting was to check the signal quality. Using ProfiTrace with its built-in oscilloscope, we found that most network segments had strong signal levels and minimal reflection. One segment, however, showed minor Electromagnetic Interference (EMI) disturbances — not enough to affect communication yet, but definitely worth investigating further.

With the electrical levels looking fine, we moved on to the network traffic. Both DP devices accepted the configuration during start-up but failed when the master tried to enter Data Exchange mode.

Identifying the root cause

Comparing the network to a healthy reference system revealed that some PROFIBUS timing parameters were slightly—or in some cases significantly — off. Even though the configuration had been reverted, timing mismatches can still have hidden consequences.

During troubleshooting, we also noticed increased current in the shield of PROFIBUS cables leaving one particular room — another potential issue that requires further investigation.

Network audit as standard practice

At the conclusion of each service visit, our engineers conduct a comprehensive on-site audit, ensuring that all systems are optimized and any potential issues are documented for immediate action. This proactive approach keeps your network running smoothly and prevents unexpected downtime.

Along the way, they detected EMI in one segment, increased shield currents, and a few other deviations from PROFIBUS installation best practices.

What can we learn?

What might seem like a small, “minor” change can ripple through a network and cause unexpected failures.

That’s why Professional Services Engineers at HMS Networks always combine troubleshooting with network auditing — ensuring reliability, stability, and peace of mind. All in a day’s work!

Want to know more about PROFIBUS best practices?

Reach out to Kent Andersson, Training & Support Engineer at HMS Networks, to learn more about PROFIBUS best practices and how to keep your network running smoothly.