(And how to make sure the answer isn’t “too many”)

Integrating a machine into a customer’s industrial network should be simple, but often, it’s anything but. Whether you're dealing with Modbus, EtherNet/IP, PROFIBUS, or CANopen, the complexity of industrial communication protocols can quickly turn a straightforward task into a multi-department project.

How many engineers does it take to connect your machine?

Is it:

a) One rockstar who knows every fieldbus on Earth

b) A dedicated team of specialists who speak fluent Modbus, EtherNet/IP, and CANopen

c) Your entire R&D department (plus one unlucky intern)

d) None: because you gave up and told the customer it’s “not supported”

If you’ve ever tried to get a machine talking to a customer’s PLC, you probably laughed (or cried) at all four options.

Networking a machine seems straightforward, until it isn’t. Customers demand compatibility with their specific industrial network: PROFIBUS in one plant, EtherCAT in the next, and legacy serial connections still hanging on in others. Each protocol comes with its own specs, quirks, certification processes, and software tools. And as soon as you support one, someone asks for another.

What should be a simple “yes” becomes a project:

Suddenly, your mechanical design team is waiting on electrical engineers, who are waiting on software engineers, who are waiting on a fieldbus expert who’s on vacation.

Sound familiar?

The irony is that most machine builders don’t want to become industrial networking experts. Your core business is innovation: making machines smarter, faster, more efficient. But poor connectivity slows you down, costs you sales, and sometimes even defines which markets you can enter.

That’s not just a technical challenge, it’s a business one.

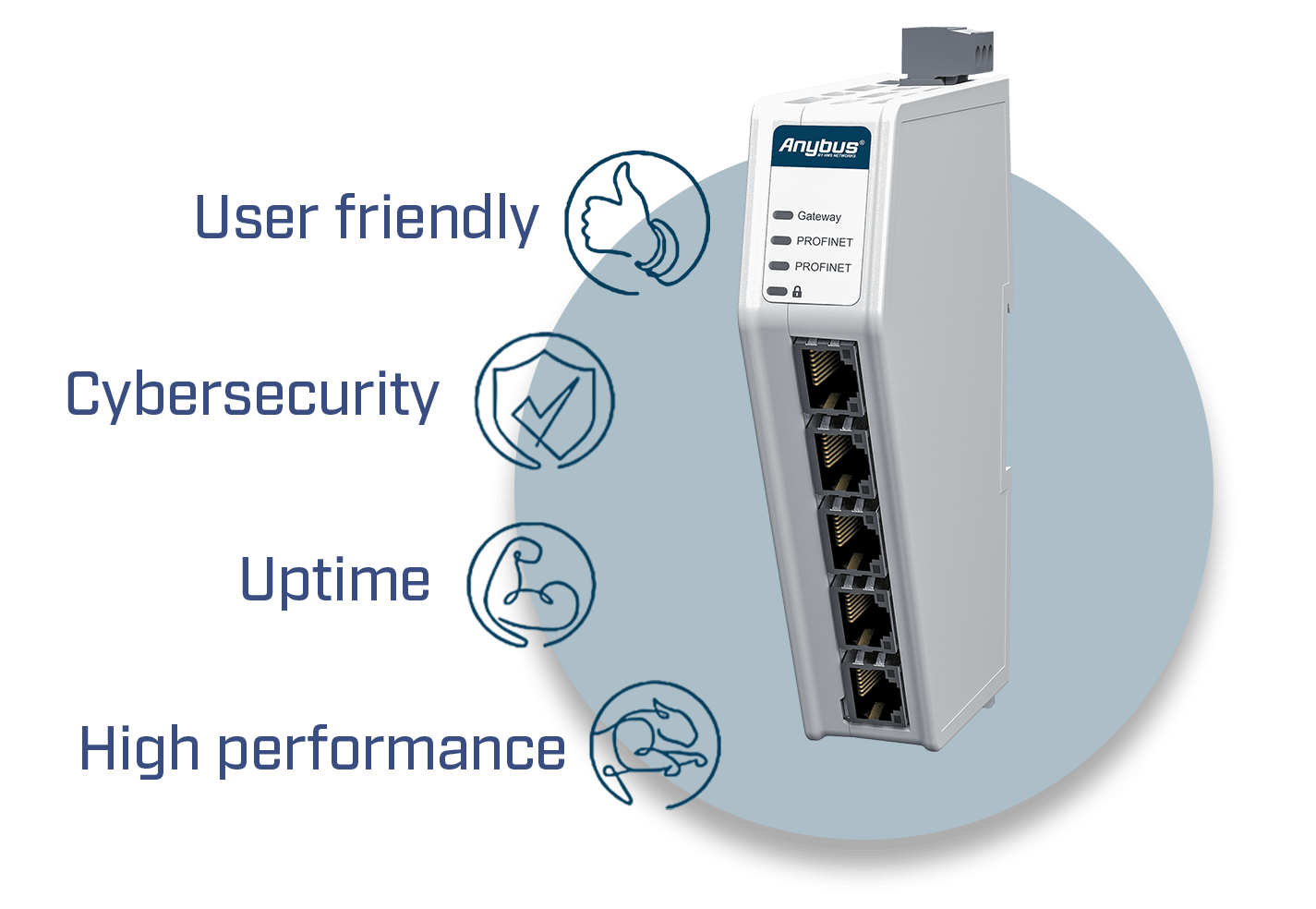

When it comes to solving industrial communication challenges, gateways are the unsung heroes. They quietly translate between protocols, bridge incompatible networks, and allow machines and controllers to talk, even when they’ve never spoken the same language. A good gateway can save weeks of development time, avoid redesigns, and make you look like a connectivity genius.

But not all gateways are created equal.

Some are clunky to configure. Some require coding skills. Others leave you wondering if they’re even working. What machine builders need is a gateway designed with usability in mind, one that speaks industrial protocols fluently, but doesn’t demand that you do.

That’s where the Anybus Communicator comes in.

Built specifically for connecting machines and devices to industrial controllers, the Anybus Communicator makes integration straightforward, even for non-specialists.

Still not convinced?

The Anybus Product Emulator lets you explore the interface and simulate configurations in a virtual environment, no hardware required. The best way to see how easy industrial networking can be.

Try the Anybus Product Emulator

So, how many engineers does it take to connect a machine?

With the right tools, just one. And they won’t need a PhD in fieldbus protocols, just a coffee and 15 minutes with the Anybus Communicator.

For more information on Anybus Gateways and how they simplify industrial connectivity, click the button below.

Thierry Bieber is the Business Development Manager at HMS Networks Market Unit in Central Europe. Thierry has over 25 years of technical and market experience in industrial communication and machine infrastructure applications, and actively participates in standardization organizations such as PI (PROFIBUS & PROFINET International).

How Many Tech Support Specialists Do You Need for a Networked Machine?

Explore how the Anybus Communicator not only simplifies integration but also reduces support load, improves customer satisfaction, and protects your brand.