Megatrends are powerful forces reshaping the future of industries. In the machine building sector, globalization and digitalization are driving significant changes in production dynamics (Petrik, 2022).

Globalization connects markets and economies worldwide, intensifying competition and accelerating innovation. As supply chains become increasingly complex, process innovation is essential to maintaining a competitive edge. At the core of this transformation lies the convergence of industrial production with IT and Internet technologies (Helmrich, Hummel & Wolter, 2020).

Digital transformation is not just a technical novelty, but both an opportunity and a necessity to enhance efficiency, reduce costs, and boost profitability throughout the manufacturing lifecycle (Pistorius, 2020; Sinsel, 2020).

Faced with rising global competition and evolving customer expectations, machine builders are under increasing pressure to adapt. Integrating digital technologies and service-based models is key to achieving critical strategic objectives:

To meet their evolving goals, machine builders must rethink how they deliver value. Servitization is at the heart of this transformation, from simply selling machines to delivering outcome-based solutions.

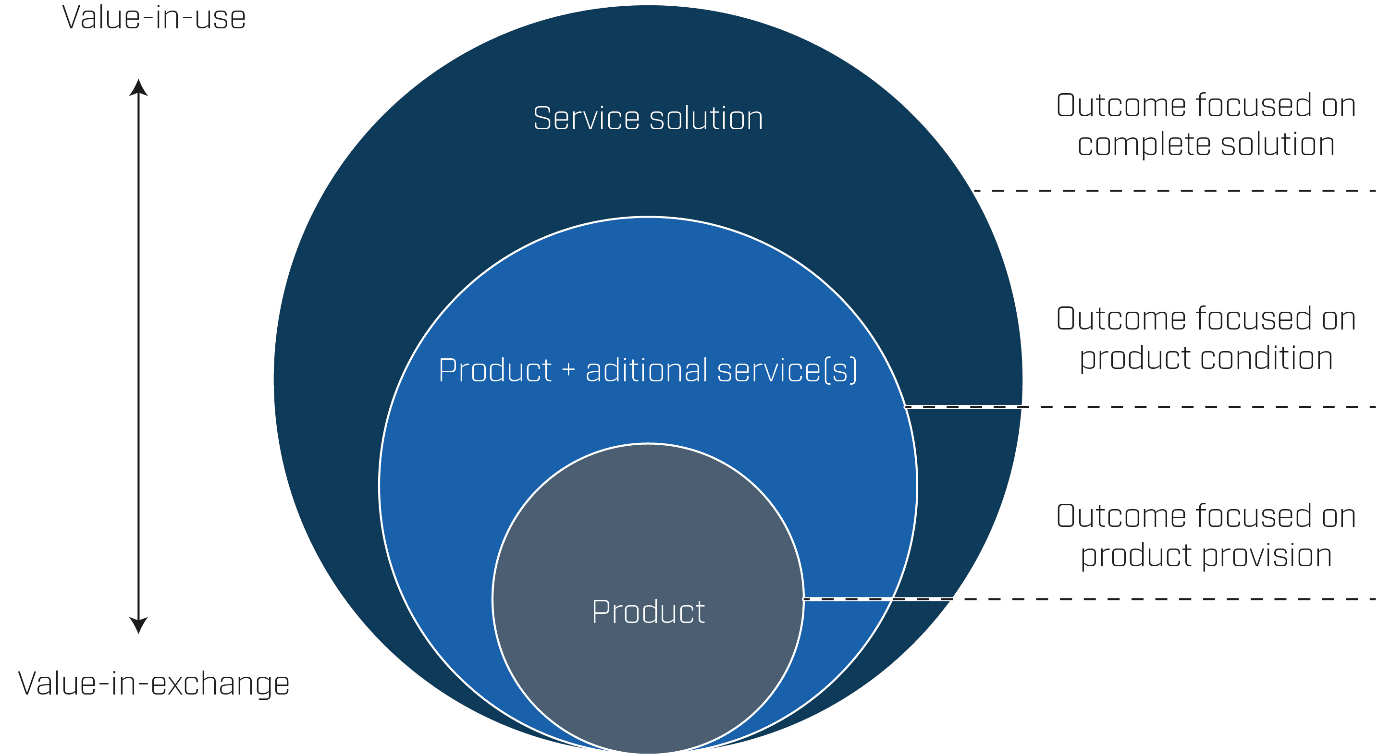

Traditionally, machine builders generated value primarily at the point of sale, with limited post-sales engagement (see Fig. 1 – Grey area).

The first step towards servitization is adding services—like training and maintenance agreements—that ensure performance and uptime, strengthen relationships, and open new revenue streams (Fig. 1 – Light blue area).At a more advanced level, the product becomes part of a broader service ecosystem. Models such as Machine-as-a-Service (MaaS) or Equipment-as-a-Service (EaaS) let customers pay for results—machine availability, production output, or quality—rather than the equipment itself. This model shifts value from the sale to the entire operational lifecycle, creating a stronger, ongoing customer experience (Fig. 1 – Dark blue area).

Figure 1: Illustration of the servitization principle

To make servitization work, real-time connectivity and data-driven insights are essential. Machines must either be equipped with additional sensors or leverage existing ones. By integrating edge gateways with PLCs and connecting to IIoT platforms, machine builders and end users gain remote visibility into performance—and can proactively manage maintenance and uptime.

As noted by Liu, Zheng & Xu (2021), digitalization provides the foundation: scalable data collection, interoperability, secure communication, and reliable storage and processing. Building on this, servitization combines products with value-added services like real-time data analytics, visualization tools, intelligent decision-making support, and enhanced human-machine interaction.

These capabilities drive next-level performance and responsiveness, giving machine builders a clear competitive advantage.

A study by Schlipf and Seebacher (2021) called “Equipment-as-a-Service Market Study 2021”, identifies both success factors and common barriers for successfully implementing EaaS models.

At the heart of successful servitization is the ability to securely collect, transmit, and act on industrial data. This is where HMS Networks makes a real difference.

With a strong global presence and deep expertise in industrial connectivity, HMS Networks delivers future-ready, scalable solutions that support machine builders and manufacturers throughout their digital transformation journey.

Working in tandem with Ewon Edge, Ewon Cloud provides a secure and scalable solution, facilitating large-scale machine fleet management, predictive maintenance, performance monitoring, and service delivery. Together, they form a powerful foundation for implementing advanced service models like Equipment-as-a-Service, helping machine builders reduce downtime, optimize support, and unlock new revenue streams through connected offerings.

i4connected is an industrial IoT platform that provides centralized, real-time, and historical data visualization for machines, production lines, and facilities. With robust user management, it enables users to monitor KPIs, performance, and alerts across multiple sites from a single platform.

SOURCES

Liu, C., Zheng, P., Xu, X. (2021). Digitalisation and servitisation of machine tools in the era of Industry 4.0: a review. In INTERNATIONAL JOURNAL OF PRODUCTION RESEARCH (Volume 61, Number 12, p. 4069–4101). https://doi.org/10.1080/00207543.2021.1969462

Helmrich, R., Hummel, M., Wolter, M. I. (2020). Aktualisierte Megatrends: Relevanz und Umsetzbarkeit in den BIBB-IAB-Qualifikations- und Berufsprojektionen. Accessed on 14.04.2025 from https://www.bibb.de/dienst/veroeffentlichungen/de/publication/show/1661

Petrik, D. (2022). Management der Zufriedenheit der Wertschöpfungspartner auf Basis der Boundary Resources im IIoT. Wiesbaden: Springer Gabler

Pistorius, J. (2020). Industrie 4.0 - Schlüsseltechnologien für die Produktion: Grundlagen - Potenziale - Anwendungen. Berlin: Springer Vieweg

Schlipf, M., Seebacher U. (2021). Equipment-as-a-Service Market Study 2021 https://mediapool.hm.edu/media/fk10/fk10_lokal/alte_website_1/05_diefakultt/03_personen/schlipf/studien/Equipment-as-a-Service_MarketStudy_2021_de_HM_Schlipf_Seebacher.pdf

Sinsel, A. (2020). Das Internet der Dinge in der Produktion: Smart Manufacturing für Anwender und Lösungsanbieter. Berlin: Springer Vieweg

Zuehlke. (2023). Digitale Services in der Industrie: Digitale Servitization beginnt mit der Neudefinition der Value Proposition. Zuelke.com. Accessed on 15.04.2025 from https://www.zuehlke.com/de/insights/digitale-services-in-der-industrie-digitale-servitization-beginnt-mit-der-neudefinition