The Challenge

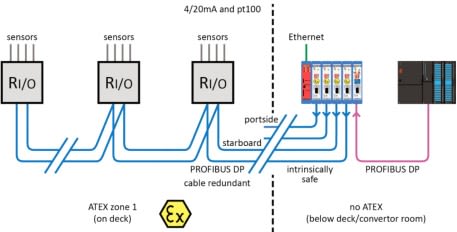

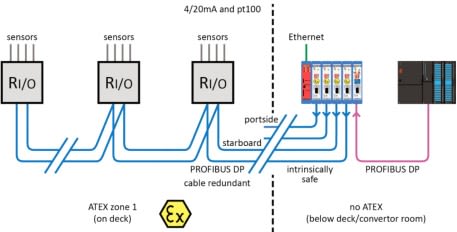

Snijders Intelligent Automation was tasked with automating four tankers transporting petroleum products in ATEX environments, where ignition risks must be eliminated at all times.

Maintaining and diagnosing PROFIBUS installations in ATEX environments is complex, while harsh maritime conditions increase the risk of cable damage. Any network failure during loading or unloading operations could result in costly downtime and operational delays.

Snijders therefore needed a solution that was intrinsically safe, remotely diagnosable, and minimized downtime through cable redundancy.

The Solution

To ensure uninterrupted PROFIBUS communication in hazardous areas, HMS Networks proposed the Anybus ComBricks solution.

Cable redundancy ensures continuous operation, even if a PROFIBUS cable is damaged — essential for harsh maritime conditions. Anybus ComBricks also enables remote analysis of network signals, detection of improper connections, and troubleshooting without entering hazardous zones. In some cases, maintenance can even be performed while tanks remain full, greatly reducing operational constraints.

“Anybus ComBricks was exactly the product we were looking for. It allows us to remotely monitor the PROFIBUS installation from a safe zone and significantly reduces the risk of downtime.”

Herman Bouman, Product Development Engineer, Snijders Intelligent Automation

The Result

With Anybus ComBricks in place, Snijders achieved safe, fully monitored, and highly reliable PROFIBUS communication across all four tankers.

Thanks to the solution: - ATEX-compliant PROFIBUS communication was achieved in hazardous zones

- Remote diagnostics reduced the need for on-site intervention

- Cable redundancy minimized the risk of downtime

- Maintenance became safer, faster, and more flexible

- Overall network reliability was significantly increased

The tankers can now operate efficiently and safely, even under the most demanding maritime conditions, with minimal risk of operational disruption.

More about Snijders Intelligent Automation

Snijders Intelligent Automation designs and manufactures high-quality electrical panels and automation systems for the maritime, offshore, and mechanical engineering industries.

With decades of experience, Snijders delivers complete solutions — from system design and engineering to installation and commissioning — tailored to demanding industrial environments.