All solutions and applications

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.

Water and wastewater utilities are complex organizations with multiple data silos and in many cases using legacy systems in critical operations. It is a challenge to integrate systems and ensure interoperability as data silos and electro-mechanical rotating equipment are normally from various suppliers with different communication protocols. In addition, connectivity for Water 4.0 is imperative for progressing in the digitalization journey, but it also raises new issues such as cybersecurity that must be considered. With HMS Networks, you get a reliable, experienced partner for the optimization of your projects.

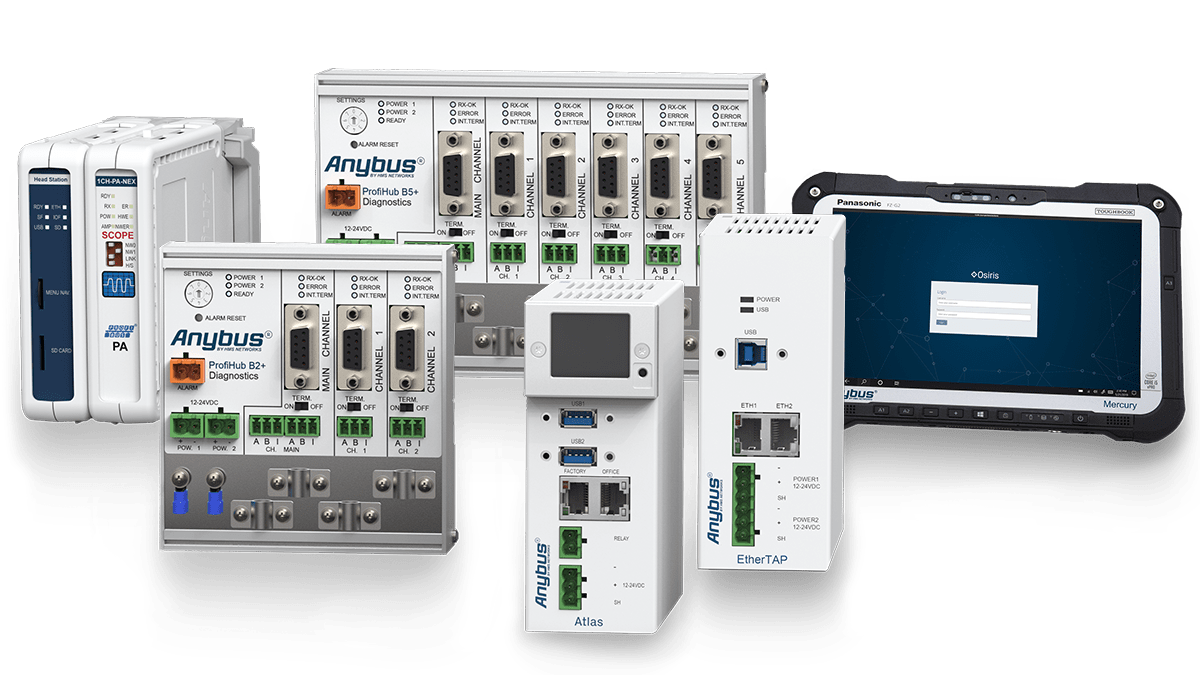

Industrial Networks are designed for optimal speed, productivity, and efficiency, playing a crucial role in the seamless operation of plants. With regular enhancements and the addition of new nodes, these networks are continuously evolving. However, these improvements can also introduce complexities, leading to potential issues and extended resolution times. Implementing continuous monitoring is key to detecting or preventing failures.

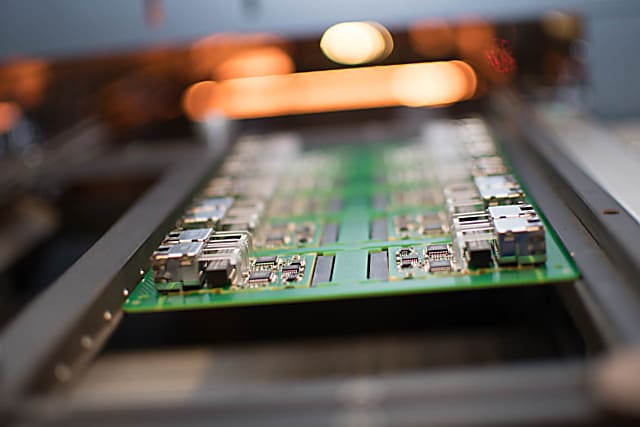

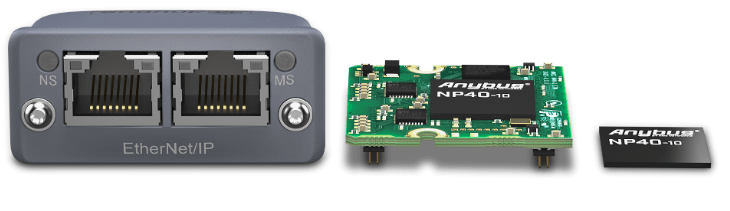

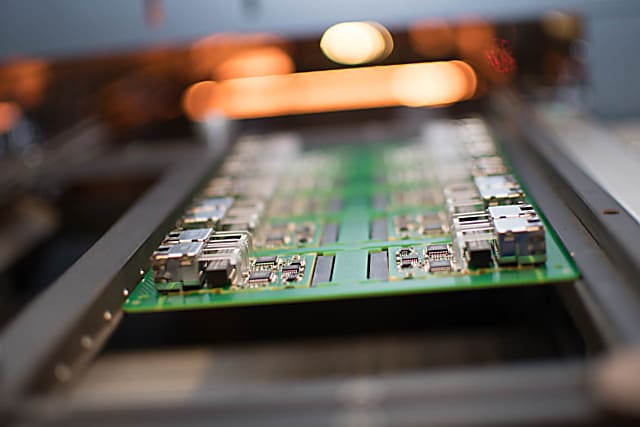

Actuators, controllers, analyzers, and sensors can be integrated into industrial and fieldbus networks using protocols like Modbus, PROFINET, EtherNet/IP or BACnet. Manufacturers need to ensure their products can connect securely and reliably to networks, but as demands for data communication grow, it is challenging for them to keep up with networking technology needs. Consequently, hundreds of companies have turned to Anybus to incorporate a pre-built communication module into millions of industrial devices.

Water treatment machines are normally controlled by an intelligent system such as a PLC. These machines require connectivity to exchange information with other machines, controllers and SCADA systems, as well as with cloud platforms for analytics and optimization. Many parameters must be monitored, such as discharge effluent, chemicals, energy consumption, efficiency, but also historical data is needed to improve the machine and provide the right support. Rental and mobile machines require monitoring of usage and location as well.

Anybus gateways will allow a seamless communication between machines by translating protocols.

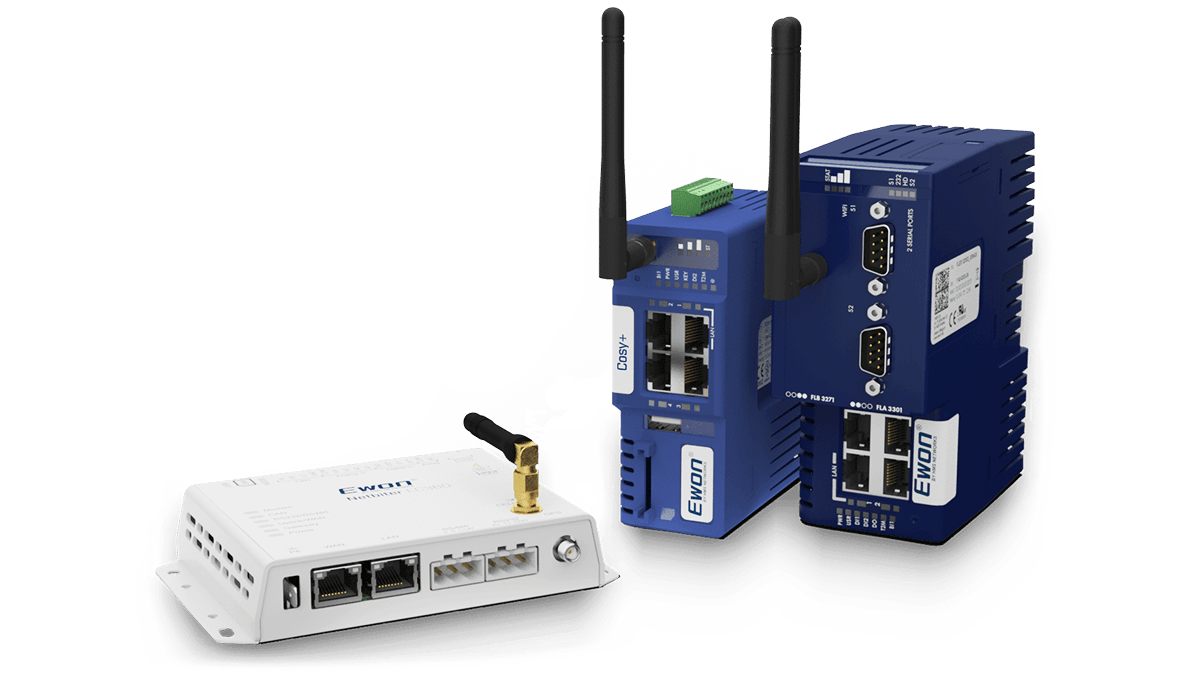

Pumps are vital for delivering clean water and managing wastewater. Many pumps work on their own in remote areas, making it essential to monitor temperature, pressure, leakages, and energy use for optimal performance.

The Ewon Flexy IoT gateway enables seamless connection and data transfer to any cloud platform, providing vital information on pumps for intelligent decision-making. It also facilitates secure remote access, allowing operators to manage pumps from any location. This capabilitysignificantly enhances response times to issues or necessary adjustments without the need for onsite presence, thereby increasing efficiency and safety.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.

How can we help you? Get technical support, place an order, talk to an expert and much more.

Check out more of our white papers on a wide array of topics.